Atoms To Bites

Impossible to Possible, Cell-Cultured Meat, and the Radical Future of Food

I’m fascinated by the threshold that defines the impossible from the possible. I talk about it a bit in Signal Leverage, where I discuss the breakthroughs in aviation and the Human Genome Project as examples of this phenomena.

Other examples are endless. Take the Track & Field feat of running a four-minute mile. For centuries racers have attempted to break this record, which was once considered a physically impossible feat.

But it wasn’t. In 1954, Sir Roger Bannister did the impossible when he collapsed across the finish line in Oxford, having run a 3:59 minute mile.

What happened next was perhaps even more remarkable. Two months after Bannister’s feat, another competing runner, Australia's John Landy, broke the threshold alongside Bannister, who again ran a sub four-minute mile. Within two years after breaking the glass ceiling for middle-distance runners, 50 runners had gone to break the record.

Since then, over 1,500 athletes have broken the four-minute barrier and the mile record has been lowered by almost 17 seconds.

This once impossible physical feat that was the crown of athletic achievement has now simply become the standard for any good professional middle-distance runner. The extraordinary quickly became ordinary.

And so I repeat one of the main principles of Signal Leverage.

Once an innovation passes over the singularity of impossible to possible or nonexistent to existent, the subsequent evolution almost always behaves nonlinearly.

Which is how we arrive to today’s essay. While Synthetic Media introduced how AI is enabling the digitization of media and content production, this post will dissect how different forces are leading to a similar dematerialization in the world of atoms of our food system.

By this, I am not suggesting that we will be consuming bits in the future. Rather, I believe our food system will become increasingly ‘artificial’, enabled by new, more efficient supply chains where meat is grown in labs. Extrapolating Buckminster Fuller’s thinking on Ephemeralization, a cell cultivated value chain will allow us to do more with less. Eventually, it will look similar to a digital value chain.

There are two driving macro premises that, if we hold to be valid, cannot both exist as true within the trajectory of our current food system. They are:

Humanity will need to produce more food in the next 30 years than we have over the past 8,000 years of agricultural production combined to keep pace with population growth by 2050.

We are currently dumping 59 gigatons of greenhouse gases into the atmosphere. By 2050, that number has to go to zero to prevent irreversible climate crisis.

It is almost certain that we will live in a future where 1 & 2 are both true — as any future where either one (or both) are false is catastrophic to human progress and should not be in the consideration set. As such, using those parameters, let’s explore why cell-cultured meat will have an asymmetric effect on getting us there, and what will happen as a result.

What is Cell-Cultured Meat?

Cell-cultured (or cell-cultivated) meat are meat products that are identical at the cellular level to their animal counterparts. These products are cultivated from a single cell using a specialized bioengineering process to create a final product with the same sensory and nutritional profile as slaughtered meat.

A simplified explanation of the process works as follows.

First, a stem cell is extracted from the muscle tissues of an animal. From there, it is added to a bioreactor and fed cell-culture media to proliferate at an exponential rate (a single sample yields trillions of cells). The cell-culture media is a formulation of dozens of ‘ingredients’ including glucose, amino acids, ions, pH buffers and (most importantly) growth factors.

Afterwards, a change in culture conditions cause the cells to differentiate into muscle, fat and connective tissues. The cells then contract to form “myotubes” — a primitive muscle fiber. The myotubes are then attached to a sponge-like scaffold that floods the myotubes with nutrients and mechanically stretches and ‘3-dimensionalizes’ them. Because of these tissues natural tendency to contract, these fibers begin to bulk, until they grow into a small piece of muscle tissue. This technique can be replicated to produce over one trillion strands of muscle tissue. Lastly, these muscle strands are combined with other muscle and fat tissues to create the final meat product.

Unlike imitation plant-based meat products like Impossible Foods and Beyond Meat, cell-cultured meat is actual animal meat — it’s just grown outside the animal. To put it another way, these meat products are made by assembling cells rather than dissembling a carcass.

While this may sound grossly futuristic, it’s not. In fact, in 1931 Winston Churchill published an article in Strand Magazine where he imagined the world “Fifty Years Hence” and posited such a possibility.

"With a greater knowledge of what are called hormones, i.e. the chemical messengers in our blood, it will be possible to control growth. We shall escape the absurdity of growing a whole chicken in order to eat the breast or wing, by growing these parts separately under a suitable medium."

A Solution for an Unsustainable System

Whether we like it or not, the food system is a pivotal battlefield in The Great War.

The Great War refers to the aforementioned battle to take net carbon emission from N to 0.

“There is only one war that matters. The Great War. And it is here."

― Jon Snow at the Dragonpit Summit

On a recent podcast with Tim Ferriss, John Doerr outlines the rules of combat:

We are currently dumping 59 gigatons of greenhouse gases into the atmosphere.

By 2050, that number has to go to zero to prevent irreversible climate crisis.

The ways we will get (mostly) there are electrifying transportation, decarbonizing the grid, fixing the food systems, not only what we eat, but how we grow what we eat. The remaining gigatons must be eliminated through carbon capture technologies.

In the background of every industry, the existential threat of climate change methodically approaches like White Walkers from beyond The Wall. Luckily, it appears that 2021 proved to be watershed year in galvanizing the collective conscious and bring carbon emissions closer to the foreground.

It is no secret that livestock husbandry comes at a substantial environmental cost. According to information from the Food and Agriculture Organization of the United Nations (FAO), nearly 77% of Earth’s habitable land and 50% of the world’s agricultural production is used to raise and feed livestock. Consequently, industrial animal agriculture is the driving cause of global deforestation and biodiversity loss. More, animal agriculture accounts for 14.5% of global green-house gas emissions and is expected to account for 81% of the remaining carbon budget under the Paris Agreement by 2050 if current rates of production continue.

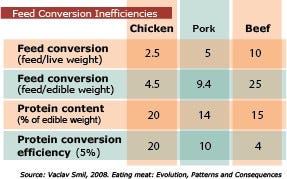

The caloric leakage of this system is even more profound. The aggregate meat-feed conversion ratio, the amount of feed needed to produce needed to produce a unit of meat for example, is 6.8 — or 6.8 pounds of feed is required to produce 1 pound of meat. That number is even higher for edible meat products. Indeed, 46% of worldwide agriculture production for livestock feed only converts into meat products that provide 7% of available food calories.

In other words, only 44% of today’s global agricultural production would be enough to feed most humans (37% + 7%). As a result, livestock feed accounts for more agricultural consumption than that eaten by humans.

The inefficiencies are blatant. A 1% decrease in livestock meat consumption would conserve over 8 billion gallons of water used for agriculture irrigation and livestock. 1.1 billion people lack access to water, and by 2025 two-thirds of the population may face water shortages. Consequently, water shortages pose legitimate social and political ramifications.

Cultured meat proves to be an efficient alternative. A research report from Hanna Tuomisto of Oxford University found complete consumption of cultured meats would decreases water usage by 82–96%.

Other environmental findings are just as encouraging. According to CB Insights, cultured meats could lead to a 72% decrease in food production’s global greenhouse gas emission and 99% decrease in less land use. Moreover, the conversion rate for cultured meats is >6x times more efficient than that for conventional meat products. It also nearly eliminates antibiotic usage compared to current levels, which the World Health Organization has called “an increasingly serious threat to global public health.”

On the consumer side, there’s been an increased interest for “clean meat.” A survey done in early 2018 from Surveygoo found 40% of Americans are willing to try lab-grown meat. Months later, a study done by Kadence International showed 66% of consumers would be willing to try lab-grown protein, and a study from Ketchum found that younger demographics are significantly more willing to try such foods — 77% of Gen Zers were more likely to eat such foods, compared to 67% of millennials, 58% of Gen Xers and 58% of baby boomers.

Consumer preference in the two largest markets — India and China — are even more open-minded. In February 2019, a global survey funded by the Animal Advocacy Research Fund revealed that 29.8% of U.S. consumers, 59.3% of Chinese consumers, and 48.7% of Indian consumers would be very/extremely willing to regularly purchase cell-based meat.

Industrial animal farming, especially pork, is structured for scale in order to optimize cost. Three-quarters of US hogs are raised on the 3,600 largest operations, each averaging more than 14,000 animals, according the 2017 Ag Census. But in the process, it maximizes the spread of disease and produces “an explosive evolutionary accelerant”, according to Rob Wallace, an evolutionary biologist with the Agroecology and Rural Economics Research Corps and author of Big Farms Make Big Flu.

In a post-COVID-19 world, the public health implications of industrialized meat production can no longer be ignored. Viruses can spread rapidly across the globe, not only with the potential to affect human, but also with the ability to decimate pig populations and cause significant food insecurity as well, as we have seen in both Africa and China over the past few years where over 100 million pigs died from Swine Fever, causing pork shortages to drive up retail prices to the highest levels in history. “The United States and Canada, the largest exporters of hog, are also the largest exporters of swine flu,” Wallace added.

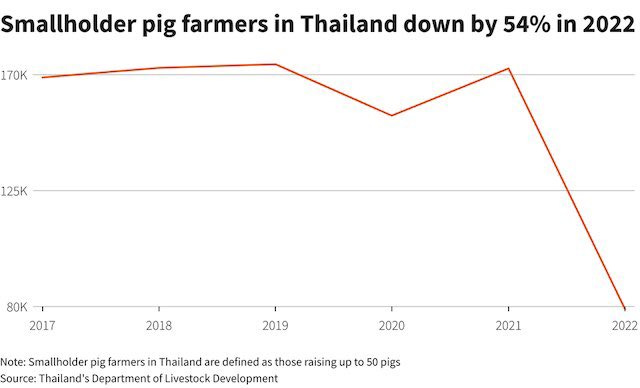

In many countries like Thailand, small pig farmers have been decimated.

Indeed, many authorities on the matter agree on the potential consequences. “Another influenza pandemic occurring at some stage of the future is exceedingly high,” said Richard Webby, professor of infectious diseases at Memphis-based St. Jude Children’s Research Hospital and director of the World Health Organization’s Collaborating Center for Studies on the Ecology of Influenza in Animals. “The chances that it’ll come from some sort of farmed animal — my personal opinion is, that’s high as well.”

The Impossible Threshold

Despite the significant commercial potential of lab-grown meats, innovation in the space has been hampered by the lack of infrastructure. And here is where things get tricky. Unlike current consumer internet and SaaS models, the industry doesn’t benefit from zero marginal cost, and unlike the semiconductor industry, as a commodity product you cannot charge a high price to compensate for the high fixed R&D and infrastructure spend.

So, on the surface, it’s a bit of a quagmire.

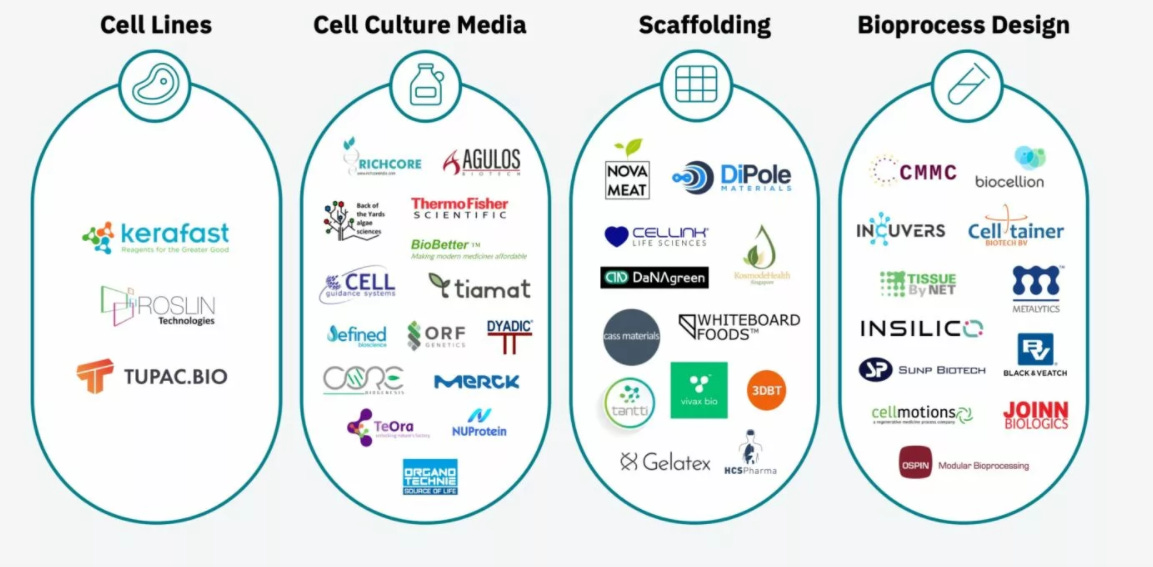

A major issue is the limited availability of cell lines — the biological materials common in research laboratories that are vital for the research and development of synthetic proteins.

According to Elliot Swartz at the Good Food Institute, Scientists working in other fields can request cell lines from the American Type Culture Collection (ATCC), a bioresource repository in Virginia that has almost 4,000 unique cell lines from 150 species. For synthetic meat researchers, however, no equivalent of the ATCC exists. Thus far, many of the cell lines necessary to research lab-grown proteins are held by a handful of private companies, and availability of suitable cell lines is extremely limited. This means higher barriers to entry for new startups hoping to enter the synthetic protein space and a slower pace of scientific advancement in the field as a whole.

“There’s basically nowhere to start yet. If anyone wants to get into this field, it takes a significant amount of resources and time to acquire and characterize a cell line in-house.”

— Elliot Swartz, Good Food Institute

In some ways, it mirrors the pre-cloud software industry. Before AWS and Infrastructure-as-a-Service, startups had to rack their own servers and build out their own infrastructure. The same holds true here, but instead of servers, startups in the space are having to build their own cell line repositories, growth media recipes and bioreactors. Almost all of the prevailing inputs have been built for therapeutic rather than commercial product purposes. Yet, it is evident that Cell-Lines-as-a-Service and Media-as-a-Service are inevitable, with companies like Orbillion building out and optimizing for specific components in this new supply chain rather than for an end product.

So, you see a bifurcation. On one end, a number of startups like New Age Meats are working to be ‘full stack’ and build their own supply chain to get to cost parity. On the other end, a number of startups like Orbillion are focused on optimizing individual components of the supply chain. Future Meat Technologies, for example, is developing and licensing a line of proprietary bioreactors and fibroblast — rather than stem cell — cell lines that they believe will can produce a greater yield of muscle tissues at a cheaper production cost. Canada’s Future Fields, is formulating and licensing a plant-based alternative to specific fetal serums (that are both expensive and controversial) that are still a commonly used growth media ingredient.

I would argue that this is actually a good thing. The vertically integrated brands are focused on the speed by which they can get a product to the market by shaving incremental costs from each part of the supply chain and sacrificing efficiency and long-term scalability. They are thinking short term, which is okay, as we are up against the clock (remember, 2050). At the same time, infrastructure startups are prioritizing cost optimization and efficiency at each specific interval of the supply chain. They’re thinking is long term, and effectively the vertically integrated brands rely on them as a hedge in the long-term.

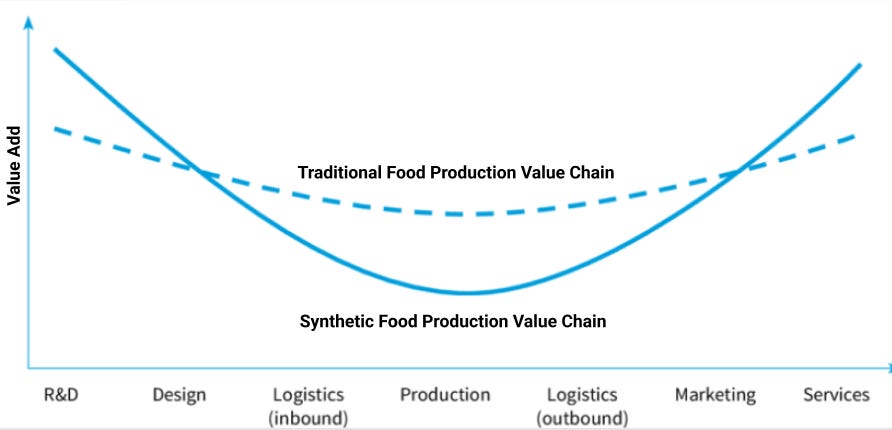

So, as the vertical consumer brands prove the impossible is possible (but perhaps not scalable), they’ll fundamentally change the risk aversion calculus of the category (discussed later) and cause an influx of new entrants into the space, who will then leverage the new infrastructure to build cheaper, better and more modular supply chains. The vertical brands will react by optimizing their own supply chains, opting to modularize some components— like cell lines — and integrate others that are highly R&D intensive. At the same time, more effort will be spent on marketing and services as a point of differentiation, which will increase demand and bring in more supply, and thus more demand for infrastructure, resulting in a rapidly maturing modular supply chain. It ends up looking like a Smile Curve.

But today the synthetic food production value chain looks like an inverted Smile Curve. Manufacturing is the greatest value add — the industry is in a race to create a manufacturing process at cost parity to regular meat — and there is less value creation from brand and long-term R&D. But over time, the variance in production will actually become significantly less than today’s current food system, where there are substantial price differences based on production — i.e. the price difference between Kobe Beef and your average Kroger steak.

Some of that is a consequence of scarcity, but scarcity is correlated to quality. Kobe beef is scarce because they are fed an expensive diet, receive daily massages, and live a specific lifestyle — all of which increase the input costs for the product and limit the scale of production. But the high input costs also increase the quality of the meats. So scarcity here is a function of high input costs — it’s really expensive and not scalable to massage cows every day — and as a result i) there is not a lot of Kobe beef and ii) the meat is high quality.

Yet, synthetic meat reduces the correlation between scarcity and quality. The meat quality is determined by the original cell line — extracting a cell from a Kobe cow costs the same as an Old McDonald cow — and the programmed conditions of the bioreactor, media culture and scaffolding technologies, which over time will become modularized. Thus, there is significantly less value-add resulting from a meat product’s ‘production’. Consequently, the value chain begins to look a lot more like today’s digital manufacturing value chain where value-add accrues to the edges and becomes more of a function of bits rather than atoms. Meaning, the value-add becomes less constrained by the laws of physics and behaves more so according to Moore’s Law.

As value creation flows to longer-term R&D, the output of single bioreactor process begins to grow exponentially, as does cost reduction. So, the competitive dynamics of the future food system changes quite substantially; competition concentrates on who can most increase output and reduce price based on advancements (via R&D) in bioreactor conditions, software programming, media culture and scaffolding — all of which are infinitely more scalable than raising cattle where there is no nonlinearity. These eventually get copied and become industry standard until the next wave of innovation enables more with less.

On the other end, there is a chance that the next massive consumer brand is born from this evolution. The value creation in R&D will create high quality commodity products unlike we have ever seen. There was a time when the question “what would it be like if everyone had a computer in their pocket?” was ridiculous, yet I think a similar advancement in ‘computational power’ will emerge in the food system. So, I think we should ask the question “what would it be like if everyone had a Whole Foods at the price and convenience of a McDonald’s?”

An Irrationally Rational Conclusion

In many circumstances, our conception of impossible and possible is not a function of the laws of physics, but a reflection of imperfect information. Consider Roger Bannister. His training as a medical doctor while racing “gave him a knowledge of physiology that no other runner who flirted with breaking the 4-minute barrier had. By measuring his oxygen consumption, Bannister discovered that running consistent lap times required less oxygen than running variable times, so he focused on running steady quarter-mile splits.”

The consequences of impossible becoming possible then become reflexive. This is a result of human behavior optimizing for loss aversion. That is, we make decisions more so to avoid failure than to reap benefit. So if we believe there is a near perfect likelihood of failure, the vast majority of us will simply not do an action, especially one with significant opportunity cost. But that changes nonlinearly as the chance of failure reduces.

So, the change in information that enables the supply of something deemed impossible to go from 0 to 1 necessitates that the difficulty — or cost — of doing that thing has decreased. This coincides with the increase in demand for that thing now that supply has increased from 0 to 1 and it has proven possible.

Said another way, new information has made it easier to do that activity and a step change in new people now want to do that activity since it has been proven possible. As more people do that activity with better information, they reduce its difficulty, which makes more people want to do it. Eventually, people realize that so many people want to do that activity that it makes sense to, instead of merely doing it, teach people how to do it better. So we get better at doing it, and on and on we go.

In the case of cell-cultured meat, the incentivizes are quite Maslowian. People need food — especially protein — and a safe place to live. The current food system is creating conditions that make our homes less safe due to climate change — and the second order effects of food insecurity — and cannot provide us with more food without making us less safe. There are clear diminishing returns to each increase in food production. It is quickly becoming negative sum. And given that premises 1) and 2) are true, the logic follows that the future cannot exist in these confines.

So, as crazy as it may sound, the bull case for cell-cultured meat is a bet on the presence of unknown unknowns — information that exists but has yet to be discovered. Yet, with each additional increase in supply, the probability of uncovering that information via increased entropy greatly increases. It is not impossible; it is and has always been possible, it’s just waiting for the right combination of information to collide.

Take the four-minute mile. By the late 1950s, enough people were attempting to break the record that the perceived benefit of breaking the four-minute mile in terms of social capital exceeded the asymmetrical cost of failure. As a result, an individual with right combination of information — in the form of skill (physical information) and knowledge of physiology — was no longer deterred by loss aversion and joined the race, proving it possible. And from there, this feedback loop accelerated at an incredibly rate, and quickly the extraordinary becomes ordinary.

Today, there are more than 80 companies worldwide aiming to create consumer-ready cultivated meat products, and dozens more have sprung up to build out this new supply chain to provide the cell lines, media, scaffolds, bioreactors, and other components necessary to support the growing industry.

It’s biology’s equivalent to Web3’s pull on top tech talent — In the past five years, hundreds of scientists and engineers have transitioned their research focus or careers toward solving challenges in cultivated meat to benefit the planet and its inhabitants.

Consequently, the probability of uncovering the unknown unknowns that tip the balance of impossible to possible is ever increasing as the supply of individuals with better information accelerates and loss aversion decreases.

Not only will that achievement unlock a completely new global food supply chain, but it will also create a completely different demand set. This is, as Rory Sutherland notes, the psychological pivot that will come from the impossible being possible and the corresponding marketing alchemy.

This is a great alchemy of marketing that by reframing something, by changing the consumer's frame of reference or comparison set, you can turn a weakness into strength.

On the demand side, the effects become second order in nature. It is less about what this technology can do, and more about what it feels like while you are doing it.

What is the psychological effects of eating a meat product entirely grown in the lab? What does it feel like to truly innovate a human experience that has more or less remained the same since the time of cavemen? What does it look like when fast and cheap no longer means low quality and unhealthy? All of these are demand questions, which I cannot answer, but all of which we should be thinking about given the direction of supply.

The marketing alchemy thus turns a weakness, an experience that over time becomes more guilt ridden for the average individual as they deal with the consequences of climate change in their periphery, into a strength — a sense of participating in the solution.

It creates the potential of a psychological moonshot, that paired with a complete transformation of the global food supply chain, can lead to explosive adoption where in the future we eat synthetic meat as the rule and farm-raised meat as the exception.